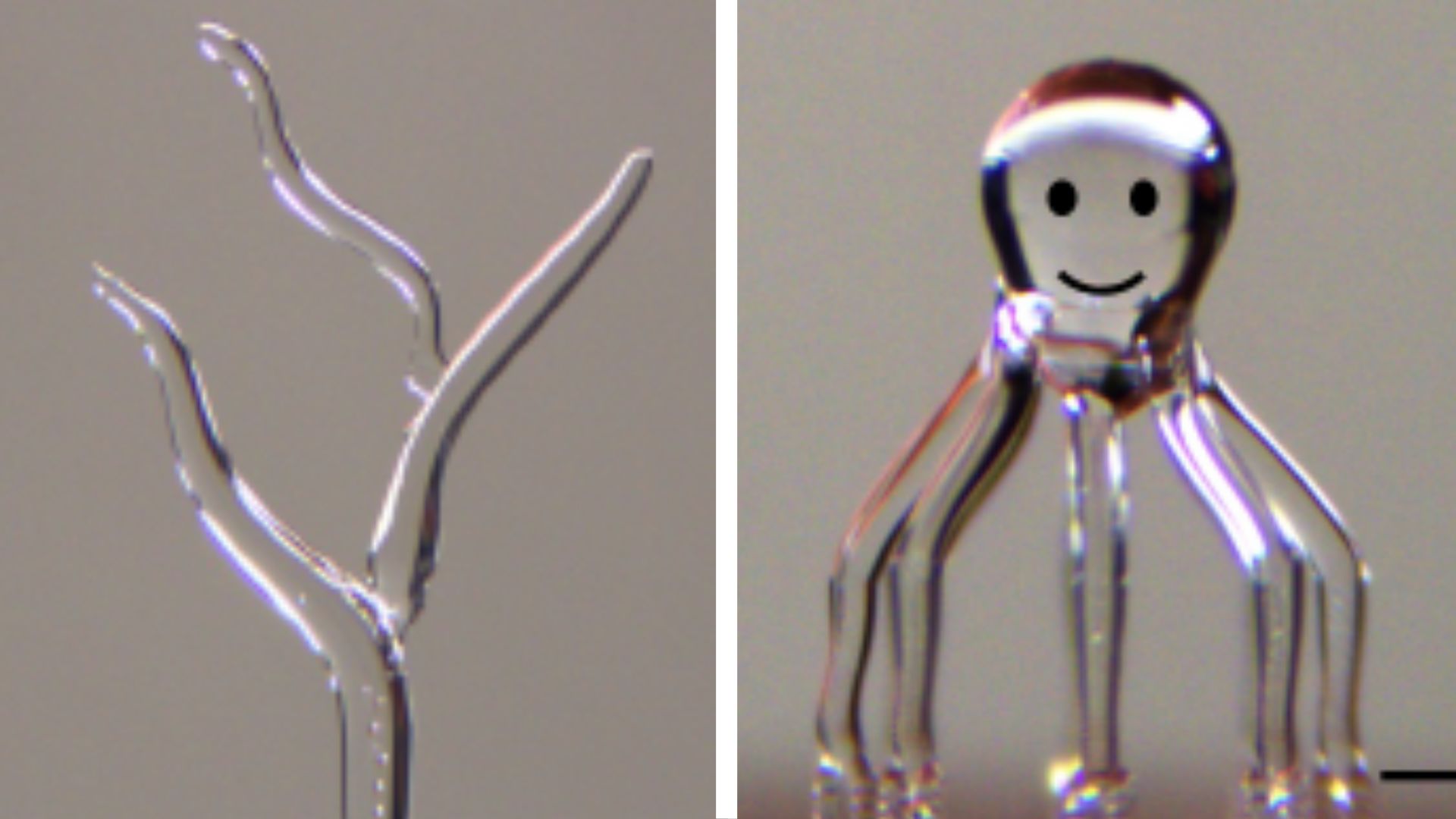

The researchers demonstrated this by printing a tree, a spiral around a pole, and even a one-and-a-half millimeter squid figure out of ice. Due to the rapid phase change of water and the strength of ice, free-form 3D printing of ice structures was possible without the need for time-consuming layer-by-layer printing or support structures.

“Controlling so many parameters was challenging,” explains Garg. “We gradually built up complexity.”

“Amazing Achievement”

Experiments were performed to determine the pressure travel, motion stage velocity, and droplet frequencies required to reproducibly produce smooth ice structures with straight, sloped, branched, and hierarchical geometries.

Burak Ozdoganlarthe associate director of the Engineering Research Accelerator at CMU, who oversaw the study, called it “an amazing achievement that will yield exciting advances.”

“We believe this approach has tremendous potential to revolutionize tissue engineering and other areas where miniature structures with complex channels are needed, such as microfluidics and soft robotics.”

In just a year, the 3D ice process could be used for engineering applications such as creating pneumatic channels for soft robotics. However, clinical application for tissue engineering will take longer.

The study was published for the first time in Advanced Science.

Abstract:

Water is one of the most important elements for life on earth. Water’s rapid phase change ability along with its environmental and biological compatibility also makes it a unique structural material for the reproducible and accurate 3D printing of ice structures. This work introduces the free-form 3D ice printing method (3D-ICE) for the fast and reproducible production of ice structures with micro-resolution. Drop-on-demand separation of water onto a -35°C platform rapidly converts water to ice. The dimension and geometry of the structures are crucially controlled by the droplet ejection frequency modulation and stage movements. The free-form approach avoids layered structures and support structures, even with overhanging geometries. Complex and overhanging geometries, branched hierarchical structures with smooth transitions, circular cross-sections, smooth surfaces and micro-scale features (as small as 50 µm) are demonstrated. As an example application, the ice templates are used as sacrificial geometries to create resin parts with well-defined internal features. This approach could open up exciting possibilities for microfluidics, biomedical devices, soft electronics, and art.