[ad_1]

Scientists in the United States have developed a method to observe the structure and mechanics of a perovskite material during its synthesis and its transition from liquid precursors to a solid thin film. The group says their work will provide new insights into how to manufacture and develop reliable large-scale processes for making perovskite solar cells.

Even if the edge of perovskite solar cells is getting closer to large-scale production, developing reliable processes for large-scale processing remains a challenge. Understanding how different processes affect film formation and structure is important to ensure that the equipment meets expectations for quality and long-term performance in the field.

However, observing these structures on a sufficiently small scale presents another challenge. And the process of synthesizing various materials and then characterizing them can be time consuming and provide limited insight. A new technique developed at Lawrence Berkeley National Laboratory in the United States enables real-time observation of the processing and formation of the thin film, and also enables scientists to observe its response to light throughout the processing.

“When people make solar thin films, they usually have their own synthesis laboratory and have to go to another laboratory to characterize it,” said Carolin Sutter-Fella, a scientist at the Berkeley Lab’s molecular foundry. “With our development you can completely synthesize and characterize a material in the same place at the same time.”

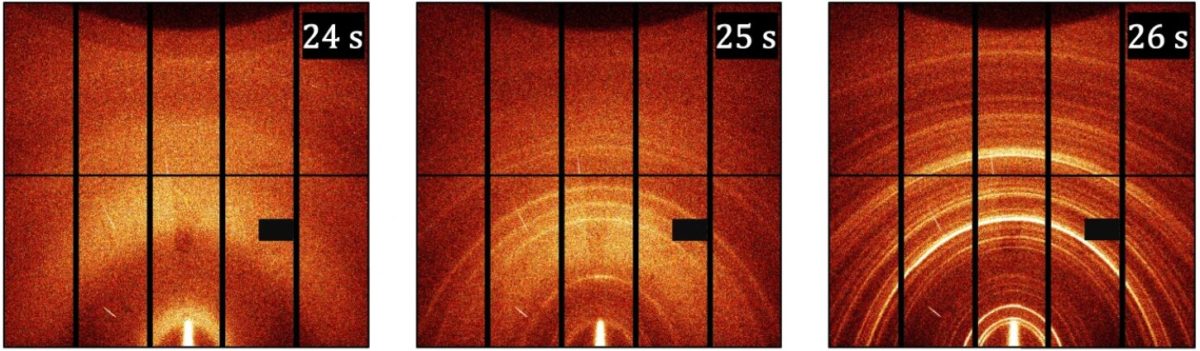

At Berkeley Lab’s Advanced Light Source facility, the group equipped an X-ray station with a laser that they can use to simultaneously observe changes in structure as it is formed into a thin film and how its response to light evolves during the process . The work is entirely in the in Nature communication.

They used the setup to observe methylammonium-lead iodide, one of the most widely studied perovskite materials, during spin-coating and gained detailed insights into four phases of film formation, including the first few seconds when the precursor begins to solidify.

Quality control

The group says their work will help other researchers better understand their processes and that it could eventually be used in industrial settings for quality control and real-time process monitoring. “The tool will enable researchers to document how small things that are normally taken for granted can have a major impact on material quality and performance,” said Shambhavi Pratap, first author of the study and now a researcher at the Technical University of Munich .

You will now concentrate on developing the observation instruments into a structure that can be used by others. “We know the research community is interested in taking advantage of this new feature on the ALS,” said Sutter-Fella. “Now we want to make it user-friendly so that more people can use this end of the line.”

This content is protected by copyright and may not be used any further. If you would like to work with us and reuse some of our content, please contact: [email protected].

[ad_2]