[ad_1]

AMHERST, Mass. – New research recently published in Scientific advances, presents a method for counting the strength-increasing entanglements in vitreous polymers – which are widely used in an enormous range of applications, from windows in hyperbaric chambers and aircraft to water filter elements, the coatings of circuit boards to the membranes used in gas separation. So far, however, scientists have not had a clear molecular view of how polymers develop their amazing strength.

image

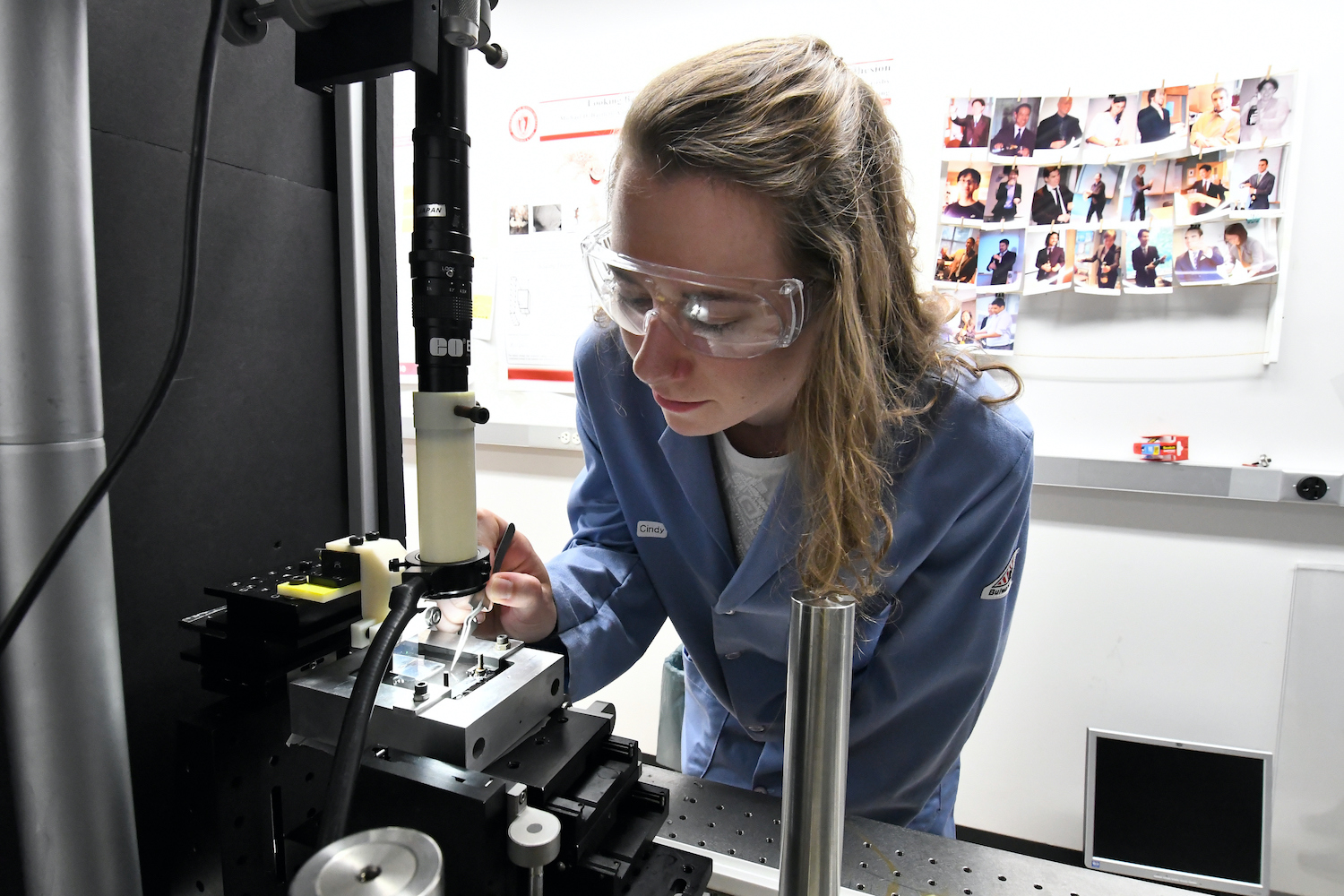

Photo credit: UMass Amherst

“Think of a polymer like a bowl of spaghetti in which many long molecules are intertwined,†says Alfred Crosby, Professor of Polymer Science and Technology at the University of Massachusetts Amherst, Co-Director of the Center for Evolutionary Materials at UMass and one of the co-authors of the paper. “Sometimes when you stick your fork in for a bite, all of the spaghetti tangles and comes out of the bowl at once.” It turns out that a polymer is like a piece of spaghetti and the longer the molecule, the more it can become tangled with other strands of polymer. When individual polymer molecules wrap around each other like pieces of spaghetti, they are referred to as “tangled” and it is these tangles that make up the ultimate strength of the polymer itself.

“But,†says Cynthia Bukowski, PhD student in Polymer Science and Engineering at UMass Amherst, and along with Tianren Zhang from the University of Pennsylvania, co-lead author of the paper, there is a compromise. “The stronger and more entangled the polymer, the more energy it needs to bring this polymer into its final shape.†It takes toxic, volatile solvents or very high heat to shape these stronger polymers, which is both ecological and economical is expensive.

So the goal is to determine the minimum number of interweaves required for each specific application and then develop an efficient polymer that is both strong, inexpensive, and environmentally friendly. But until now researchers have long been at a loss to find out exactly how to count the important entanglements.

Bukowski, Crosby, Zhang and Robert Riggleman, Professor of Chemical and Biomolecular Engineering at the University of Pennsylvania and co-author of the article, developed an innovative combination of computer-based simulations that approximated the interaction of polymer molecules in real life with an experimental process that produced a polymer film with a thickness of 100 nanometers (or 500 times smaller than the width of a human hair) and stretched to the breaking point. The team then developed a theory that allowed the simulation to accurately predict their experimental results – and when they got them, they knew that this model was close enough to real life to accurately count the entanglements of a polymer.

“That was our breakthrough,†says Crosby. “We could change the number of entanglements in the polymer and the model would give us an accurate picture of how the molecular structure of the polymer controls the strength of the material.”

The researchers, funded by the National Science Foundation, found that not every interweave actually adds to the ultimate strength of the polymer, and that there are ways to fine-tune the critical load-bearing intertwines to maintain strength and the energy required to process them decrease for a range of uses.

“It’s exciting to finally understand what is happening at the molecular level,†says Bukowski. “And we hope that our research will contribute to the next generation of polymer materials.”

[ad_2]